A Mystery Box

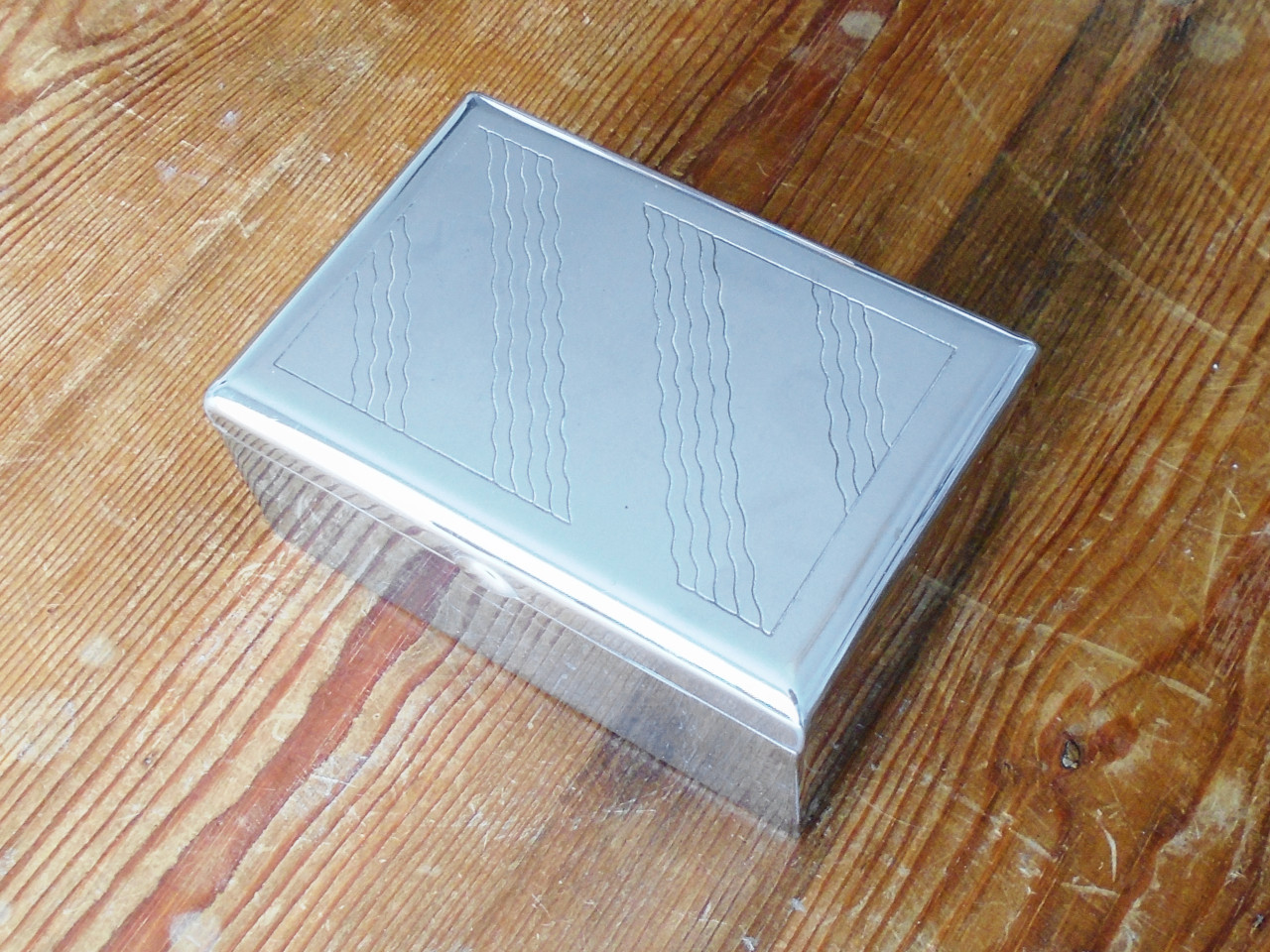

This little box looks ordinary enough at first sight. Made of a bright and highly polished stainless steel, it has a more or less abstract pattern of wavy lines on the lid. Inside it is lined, and divided in two front-to-back, with sandalwood in the usual way. It is just about big enough to hold cigarettes, or would serve well as a jewellery or trinket box. Its Art-Deco-to-Pop-Art motif, abstract but evocative, could date from anywhere between 1930 and 1980. So far, so unremarkable; I am told that it turned up in a collection of junk on eBay, being sold off for peanuts.

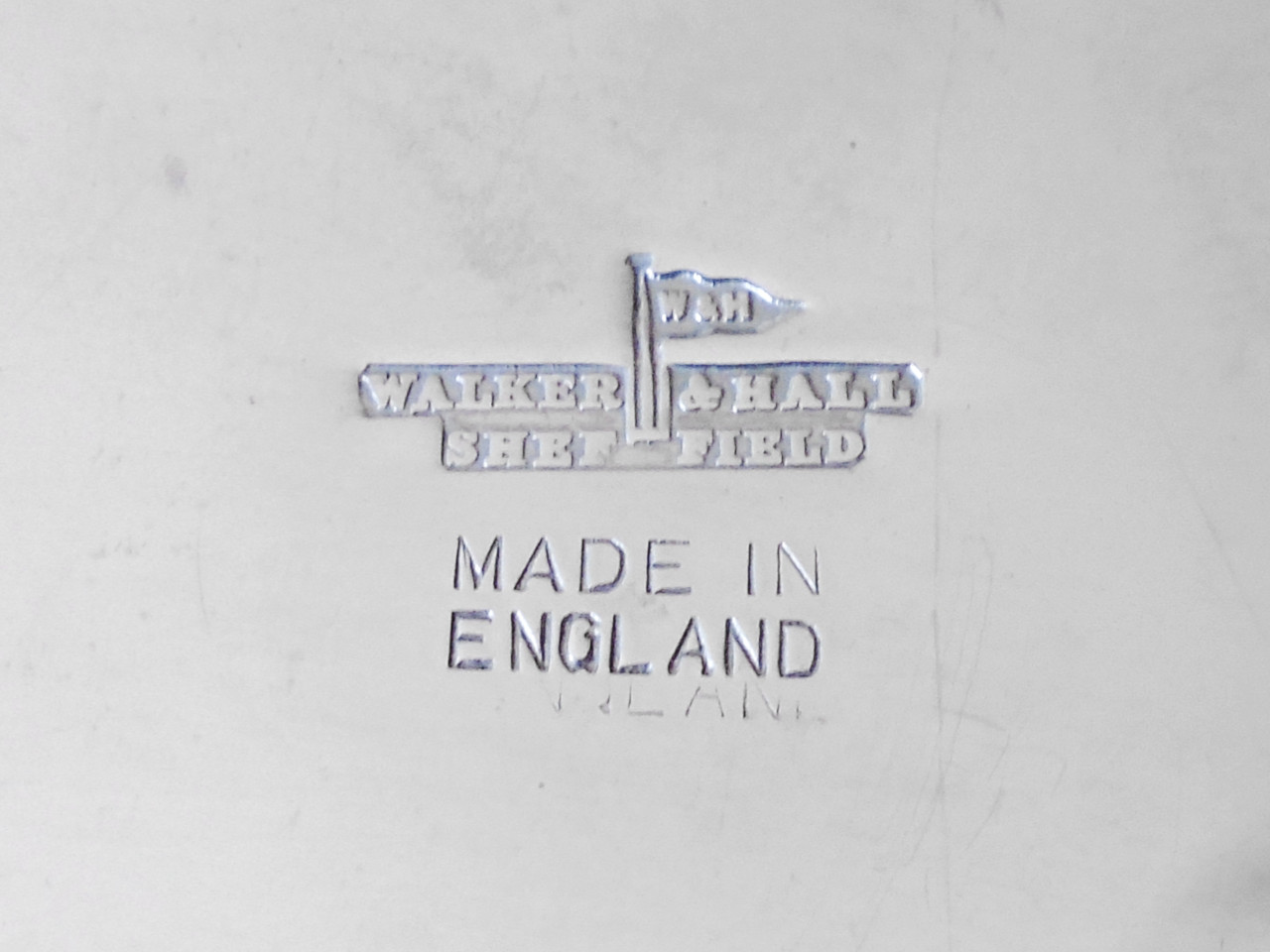

The "England" betrays signs

of a double strike.

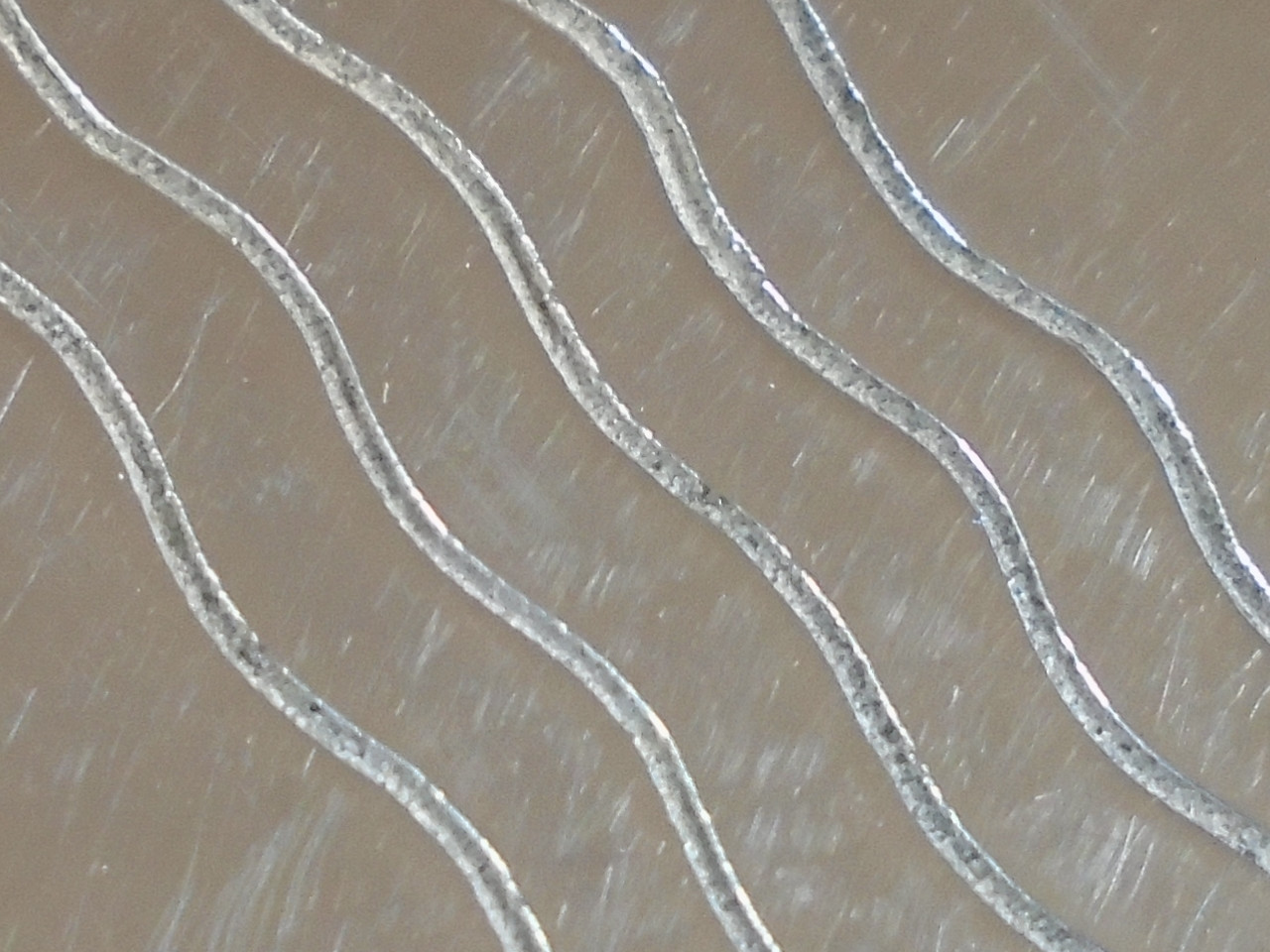

My camera struggles to show

the rough spark-etched texture.

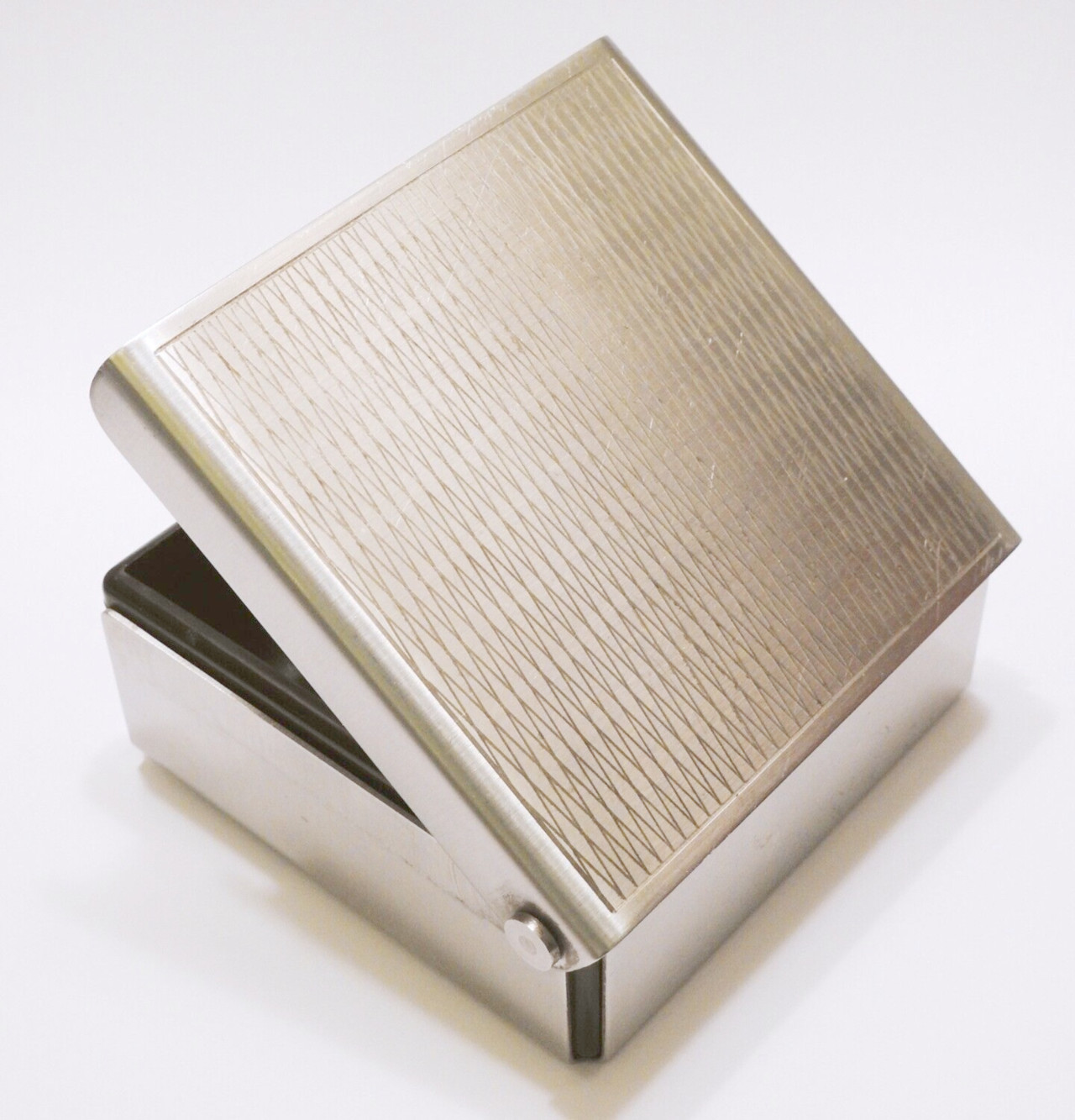

Bramah cigarette box by Mellor, ca.1968.

But now, here's the oddity, or rather two of them - and you have to really know your stuff to spot them. Underneath it is stamped "Walker & Hall Sheffield" along with their well-known W&H flag logo and, in cruder lettering, "Made in Britain". That last stamp is odd because there is a faint double-strike of the "England"; the stamp evidently bounced and got knocked down a second time when it was struck. Now, the W&H craftsmen were deeply proud of their craftsmanship; tools might wear sloppy, designs become deeply unfashionable, but the workmanship had to be worthy of self-respect. But the oddest thing about it is that it should not exist at all. W&H are not known to have made stainless wares such as this. They made stainless holloware – teapots, jugs, etc. – around 1960, to go with their cutlery, but not other things like cigarette/trinket boxes. All the rest was siverware, what's more the range was slashed to a fraction of its former size. This is the only such box of theirs I have ever come across, which was not silver.

In seeking some context for it, I am drawn to the story of their relationship with Old Hall, which the two comanies established in the late 1950s. Old Hall had long been renowned for their bright and shiny stainess steel products. At the time that W&H were developing their consultant desinger David Mellor's ideas for the mass production of stainless steel cutlery, Old Hall had taken on Mellor's contemporary Bob Welch in the same capacity, and they by contrast wanted to expand into cutlery. They agreed to collaborate: the two designers would jointly develop a set of cutlery and holloware. W&H would make the cutlery while Old Hall made the holloware and flatware (serving dishes). In this way, prduction numbers would be high enough to justify the cost of setting up a mass production line and keep prices competitive. Each company would then stamp on its own mark and sell both lines under their own brand. W&H named it "Spring", Old Hall chose "Campden". In the event, W&H not only made the cutlery for Old Hall, but stamped it as well. However the holloware did not take off, and when W&H eventually introduced it for their Symbol range, they made it themselves. Yet the deal was, as far as we know, confined to tableware. Nowhere in all these plans did Old Hall's stock in trade feature; such things as stainless candlesticks, ashtrays, boxes and so on.

During all this, my father was Managing Director of the company. I was a small boy, often away at school, and these days my memory is not as trustworthy as it used to be, but I seem to recall Dad telling me one day that the holloware side of things had been attempted at W&H, but had not gone well and had been abandoned. I cannot help but wonder whether this stainless box with the double-struck stamp is a child of this aborted plan. One can imagine a fine craftsman, long accustomed to relatively soft and pliant metals such as Britannia metal, nickel-silver and of course silver itself, being caught out by the hardness and resilience of stainless steel. In the past, he would never have needed to place a backing piece behind the workpiece where it was struck; the metal would have been sturdy yet malleable enough for the stamp to do its job regardless. But stainless steel is tougher and more resilient, and is used in thinner sheets. Striking that "Made in Britain" stamp on the tough, springy base without a backing piece could easily have ricocheted and been the cause of that double-strike.

Can the bright finish offer any clues? Probably not. 18/8 austenitic stainless steel, with small amounts of both chromium and nickel added, was developed in 1924. It should come as no surprise that this was another child of Sheffield, a town renowned probably even more for its steel than its early silver plate. WH Hatfield brewed it up at steelmaker Firth Brown, who sold it widely under the name of Staybrite. It is almost certainly the material used for this box. Old Hall are said to have used it, and were known for their bright, shiny stainless ware. For Spring/Campden, W&H developed a more muted and slightly greyer finish, typcally satin-textured, which leads me to wonder if they had moved to a more workable grade for volume manufacture. Or perhaps they just chose not to polish the knife blades to a high sheen. Either way, it seems quite likely that they would have started their stainless trials with a high polish - especially if Old Hall were using it habitually.

The "Made in Britain" stamp might offer further clues. Why such a severely square and simple "less is more" typeface? And why Britain not England? To me these suggest echoes of the postwar Festival of Britain era, a time when cheap American and Japanese imports were beginning to threaten the old idustrial base that had served an empire. This again would chime in with the failed Old Hall project.

Then there is the slightly rough texture of the etched lines in the lid. Close inspection revelas tiny blobs of molten metal stuck here and there. Where two lines meet at an angle, the acute corner may show small signs of bluing under intense heat. The lines have clearly been rather crudely spark-etched by following a master pattern with a pantograph arrangement. This kind of wire-cut spark erosion came into widespread use in the 1960s. Again, my dubious memories of sixty-five years ago, back to the late 1950s, recall a visit to the W&H Electro Works, where I saw an early and (on that day) only partially satisfactory pilot of spark-etching hallmarks in knife blades too thin to be stamped; it would have been either Spring or its forerunner Pride. As I recall, it was a bought-in piece of new technology and nobody quite knew how to get it right on a production basis. W&H had married it up to a pantograph they already used for more traditional purposes. Ten years after Spring/Campden, David Mellor designed a stainless cigarette box for Bramah; it shows an altogether more sohisticated control of the decorative process. All of which provides perhaps the strongest evidence available for the Spring/Camden era.

So there seems a good possibility that this box is one of the few non-cutlery pieces to come out of the joint design and sales initiative, or at least from that era of the business. Perhaps it is some prototype piece that never entered production and was taken home by somebody (my dad once had several such). But questions remain. Was this one of David Mellor's designs, with or without the collaboration of Bob Welch? Was it made by W&H or Old Hall? Or, am I barking up completely the wrong tree? Mellor's heir and historian Corin Mellor has never seen anything like it either. Did this unknown foray into stainless boxes and primitive spark-etching date from the 1930s, in an attempt to compete directly with the likes of Old Hall? But as far as I know, that was before the time of commercially-available spark etching systems. Might it alternatively date from the late 60s to 70s, the era of British Silverware/Mappin and Webb when W&H ceased manufacture and was reduced to a brand and an ever-shrinking and cheapening chain of high-street shops? The company had a long track record of buying in stuff they did not manufacture and putting their name on it. But the quality of the spark etching should have been far better by then. I'd love to hear from anybody who can shed light on this enchanting little box of mysteries.

Updated 14 July 2023